Choosing the correct caster wheel is critical in industrial and commercial settings. When heavy loads must move reliably and safely, the type and size of caster make a surprising difference in productivity and floor life. Widely used for their durability, phenolic wheel options deliver high strength and resistance to chemicals and oils, making them a top choice for warehouses, factories, and institutional environments.

Facility managers should consider caster wheel sizing, load-bearing limits, and resilience to hazards to avoid wear and equipment damage. Phenolic casters are durable for use on flat surfaces in dry environments, but should be kept away from harsh alkalis. Proper diameter is essential; larger wheels (5”-10”) enhance performance on uneven surfaces and prolong caster life by better weight distribution, while smaller wheels (3”-4”) are designed for short distances.

Menu list

Calculating Load Capacity for Phenolic Casters

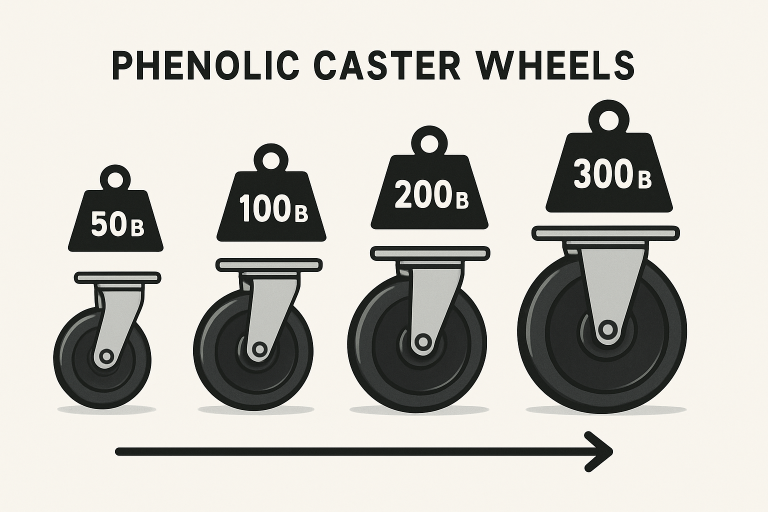

Determining load capacity is a crucial consideration for ensuring safe caster wheel performance. Misjudging this specification risks both personal safety and the loss of expensive equipment. To calculate the correct caster load capacity, add the combined weight of the equipment and the maximum anticipated load. Divide this figure by the number of casters installed, but also plan for uneven loads.

For safety and security, it’s a best practice to assume the worst-case scenario in your calculations. Occasionally, only two wheels may bear the majority of the weight (such as when a cart crosses an uneven threshold). Always select casters with a higher load rating than strictly required, as this helps accommodate unexpected strain intervals.

Environmental Factors to Consider

Phenolic wheels excel in dry, stable environments, gliding smoothly across concrete and resisting flat-spotting even when at rest under heavy weights for extended periods. However, if your facility features wet or extremely rough surfaces or regularly handles strong acids or bases, consider alternative wheel materials. While phenolic casters are heat-tolerant and chemically resistant to most industrial fluids, prolonged submersion or exposure to extreme pH levels can degrade their structural integrity over time.

The installation environment isn’t limited to surface characteristics. Temperature is also an essential factor. Oven carts, autoclave racks, and freezers can benefit from the wide operating range of phenolic casters. Still, consistent temperature extremes approaching the material’s threshold can stress the wheels, so regular inspections are advised.

Maintenance and Maximizing Wheel Longevity

Even with the best wheels, maintenance is required. Inspect casters regularly for cracks, chips, or other signs of distress—especially if they ride over expansion joints, debris, or non-smooth surfaces. Keeping bearings lubricated helps keep wheels turning easily and quietly. Clean wheels frequently to remove grit or residue that could cause uneven wear, and replace any casters showing significant wear to avoid damage to merchandise or injury to staff.

Diligent maintenance ensures your investment in phenolic wheels pays off over the long haul. In environments where chemical resistance and temperature tolerance are required, ensuring the casters remain clean and dry can drastically extend service life.

Conclusion

Selecting the right phenolic caster wheel size and load capacity isn’t just a matter of convenience—it’s a fundamental safety consideration for your material handling operations. By measuring the total weight, considering travel distances, evaluating environmental exposures, and maintaining your caster wheels, you’ll enjoy safer, more reliable, and longer-lasting equipment. If your needs are complex or your environment particularly harsh, consulting with a caster specialist for additional guidance is always a wise step.