In modern industrial automation, proximity sensors are extremely crucial because automation systems can detect an object’s presence or absence without any contact, eliminating the need for a switch or a mechanical part. A wide range of applications utilize these sensors, such as in object tracking and sorting, material handling equipment, safety devices, and robotic systems. Given the availability of several kinds of proximity sensors, it can be challenging to select the right one for a particular project. This article focuses on the most common types of proximity sensors, their uses, and how to pick the right one for your project. Additionally, we will examine the impact of industrial automation distributors in fostering the right sensor supply for your automation systems.

Menu list

What Are Proximity Sensors?

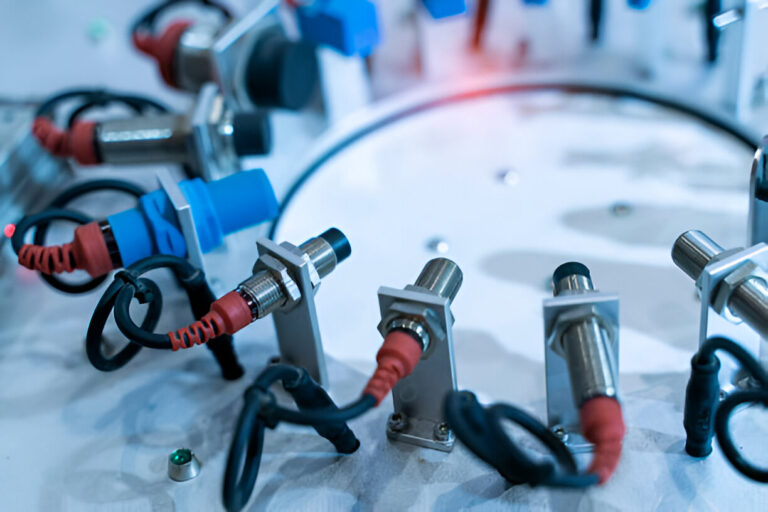

A proximity sensor is a device that can sense an object’s presence without any physical contact with it. The operating principle of proximity sensors includes electromagnetic induction, capacitance, and ultrasonic waves. Inductive, capacitive, optical, and ultrasonic are a few variations of proximity sensors. Each of these types of sensors has distinct characteristics, and selecting the correct sensor type is crucial to the success of an industrial automation project. In addition to these other fields, proximity sensors are widely used in manufacturing, robotics, automotive, and many other industries. In automation systems, they ensure the correct operation of machines and processes. As industrial automation components, the reliability, precision, and durability of proximity sensors make them essential to the solution. Moreover, the use of proximity sensors in automation systems helps minimize human involvement, which increases the levels of safety and efficiency at the workplace.

Important Kinds of Proximity Sensors

Different types of proximity sensors are available, and each type is useful for a certain application. One of the most widely used types in industrial automation are inductive proximity sensors. They work by creating an electromagnetic field around the sensor which detects metal objects. When a metallic object is introduced into the field, it causes a distortion of magnetic flux and the sensor recognizes the change. This type of sensor is used in manufacturing, automobile industry, and in other material handling industries. On the other hand, capacitive proximity sensors detect both metal and non-metal materials by measuring alterations of capacitance. Therefore, these types of sensors are capable of detecting plastic, glass, or even liquids. They are often used in packaging and level sensing applications. Optical proximity sensors work by sensing light. As a result, they have great accuracy and are able to sense farther compared to other sensors. They are ideal for automated inspection systems and other material handling processes. Lastly, ultrasonic proximity sensors work by detecting sound waves. They are able to detect virtually any kind of material and are particularly useful in measuring the distance to objects or the level of liquid in difficult environments. Knowing these types and their applications is important in deciding which sensor to obtain for your automation system.

How to Select the Best Proximity Sensor for your Application

The selection of the appropriate proximity sensor for your industrial automation project hinges on multiple considerations. For starters, stump up the type of the object you would like to detect. For example, when detection of metal objects alone is needed, an inductive proximity sensor would work perfectly. When on the other hand, the detection of nonmetallic materials or both nonmetallic and metal objects needs to be done, then capacitive or even optical sensors would work perfectly. Finally, factors such as the environment in which the sensor will be deployed also plays a big role in the selection process. Environments that are considered hostile or extreme in moisture, dust and even very high or low temperatures would be best suited with inductive sensors which are more robust in such environments. Moreover, the level of tolerance of the sensor also matters significantly. Where longer distances need to be measured, ultrasonic sensors would be the best to use as they tend to supply the longest detection range. The speed of response needed for your application is another aspect. NPN proximity sensors are noted as having a short response time which is critical in high speed operations like automated sorting or assembly lines. Lastly, allocate a budget for your project and bear in mind the expenses. While these features may be needed, specialized applications may require ultrasonic and optical sensors which come at a higher price.

Looking into these factors will guarantee that your sensor selection process is efficient.

The Contributions of Industrial Automation Distributors in Sensor Selection

Industrial automation distributors are essential when businesses have to select the right proximity sensors for a project. These sorts of distributors tend to sell a variety of sensors from a number of manufacturers, as well as give guidance on the best sensor selection for the particular needs of your automation system. These professionals are quite knowledgeable when it comes to sensor technologies and can help find the right proximity sensor from an NPN proximity sensor to different types like capacitive, ultrasonic, or optical sensors. Distributors also offer supporting services like procuring certain models of sensors, helping set them up, and even diagnosing issues where necessary. They will confirm that the sensors they supply are suitable for your system, helping enhance the efficiency and reliability of the automation process. Collaboration with experienced industrial automation distributors means that you access the right sensors and solutions your project requires making sure that the performance of your automation system is improved. Beyond this, they assist the clients with after sale services to make sure the sensors are functioning effectively for the expected duration.

Conclusion

Proximity sensors are critical for any industrial automation system to work efficiently. The most commonly used proximity sensors—inductive, capacitive, optical, and ultrasonic—are most suitable for specific purposes, which depends on the material to be detected and the environment in which the sensor will operate. Knowing the different types of sensors and their uses enables users to pick the most appropriate sensor for a given job or project. Distributors of industrial automation products also provide important services and products in order to make certain that the sensors installed into the system work seamlessly. It does not matter if your need is an NPN proximity sensor or something else, the right distributor will make your industrial automation system work the best. With the correct selection of the sensor, automated industrial systems can boost the level of reliability of the system while minimizing the time wasted on maintenance and repair across many industrial-based tasks. The use of these selected best performing proximity sensors is not limited to automated systems only but to a variety of industrial use where the need for improvement in performance is required. Making an appropriate selection when it comes to proximity sensors not only leads to better results, but also more efficient processes that are safer in automated settings.